Industry Blog

Explore the latest news about drone technology, data solutions, and Firmatek’s perspective across a range of industries.

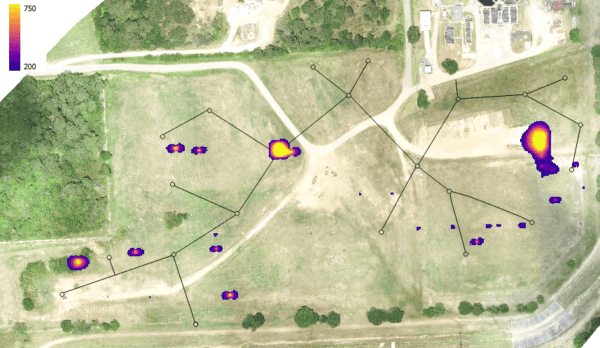

Firmatek’s Methane Detection and Mapping Services Help Improve Environmental Compliance

In early 2022, Firmatek acquired our first methane detection sensor. After a long R&D process and demonstrations ...

Exciting Upgrades to Kespry Cloud: Notifications & Premium Deliverables

We’ve been extremely busy over here at Firmatek, designing new approaches and features to better help our customers...

Kespry Cloud New Feature Release: New Reporting Capabilities, Renaming of Pile ID’s

We’re excited to let you know about some of the new features that are being added to Kespry Cloud. New Reporting Ca...

Transforming Electric Utilities Inspections: Skydio Drones are the Right Tool

Firmatek is transforming the way electric utilities inspect their assets with the use of Skydio drones. In a recent p...

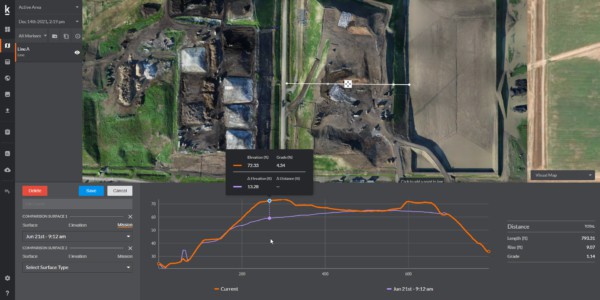

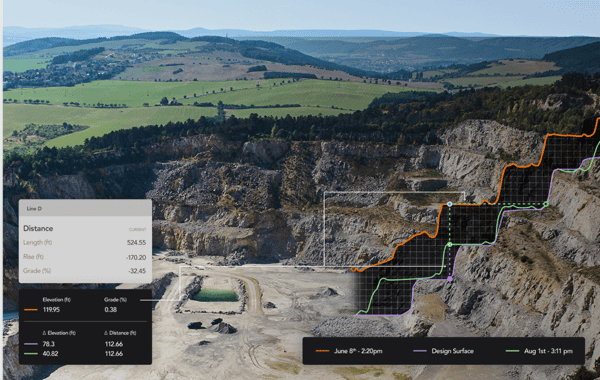

Kespry Cloud New Feature Release: Cross Section Reporting

We’re excited to announce the release of our newest reporting capability within our Kespry Cloud platform. The new ...

Kespry Cloud Enhancements & Availability for All Firmatek Customers

We are excited to announce several enhancements to Kespry’s functionality. These enhancements were rolled out in mi...

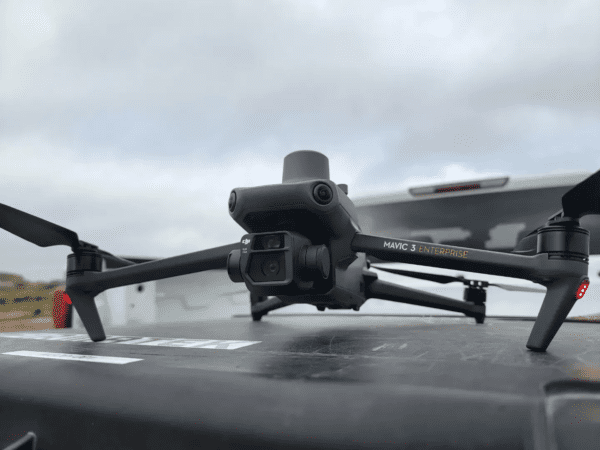

Firmatek Announces Integration with DJI’s Mavic 3 Enterprise

We at Firmatek are thrilled to announce the integration of the DJI’s newest commercial-grade mapping drone into the...

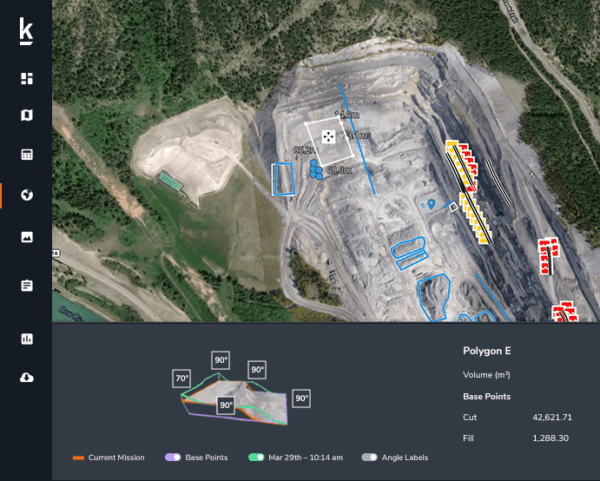

An Enterprise Solution for Inventory Management & Mine Planning

Clients have been searching for years for the right solution that has all the software tools the team needs but doesn...

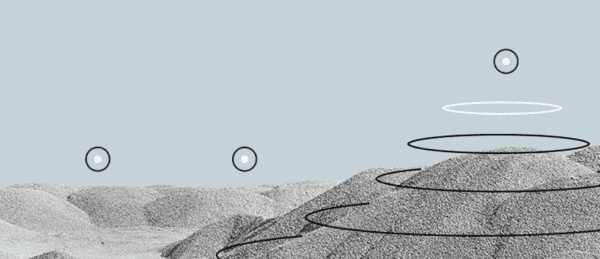

Kespry for Landfills

Kespry helps landfill operators improve their site operations The ever-changing physical state of landfills creates c...

Firmatek and Kespry – New Cloud Offering

New cloud offering delivers data access and analytics to your fingertips Two leaders combine to provide industry-focu...

Firmatek + Kespry Cloud, Part 2

As a Kespry client, you collect and analyze your data in Kespry Cloud. Kespry Cloud empowers you with the tools you n...

Firmatek + Kespry Cloud, Part 1

Firmatek acquired Kespry in late 2021. These two industry leaders coming together empowers our clients in the aggrega...

3 Ways Drones Make Aggregates and Mining Companies More Profitable

Aggregates and mining sites are complex structures composed of many moving parts. If any one part of a system were ...

Geospatial Engineering Technician, Bryce Vascik, Published in AGU’s Journal of Geophysical Research

We are excited to announce that Bryce Vascik’s thesis was recently published in AGU’s Journal of Geophysi...

Firmatek Announces Acquisition of Kespry

We are excited to announce that Firmatek has acquired Kespry’s drone-based aerial intelligence platform. The ac...